Oke nkenke: Imeghe ike nke TCT hụrụ Blades na ngwa ịkpụ ọgbara ọhụrụ

Dọkịta na-awa ahụ ihe: ka TCT Technology si agbanwe ịkpụ

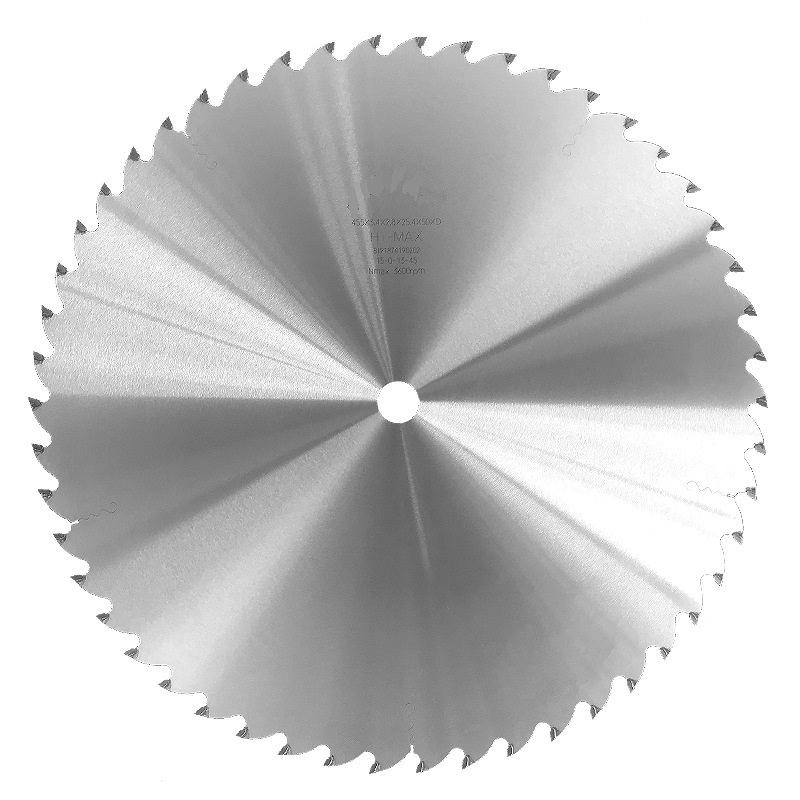

Tungsten Carbide Tipped (TCT) agụba na-anọchite anya ọnụ ọgụgụ teknụzụ ịkpụ, na-ejikọta nkenke ịwa ahụ na ogologo oge ụlọ ọrụ. N'adịghị ka agụba a na-emekarị, TCT na-ejikọta ezé obere ọka tungsten carbide - klaasị ihe kacha sie ike nke obere diamond - brazed ma ọ bụ kpọgidere n'elu ígwè ígwè dị elu. Nhazi ngwakọ a na-enye arụmọrụ na-enweghị atụ n'ofe osisi, igwe, ihe mejupụtara na ihe ọpụrụiche, na-eme ka ọ bụrụ onye mmeri na-enweghị mgbagha na ụlọ ọrụ ọkachamara na ntọala ụlọ ọrụ n'ụwa niile.

Core Engineering: Anatomi nke Peak Performance

1. Advanced Material Science

- Ezé Tungsten Carbide: Ejiri ya na carbide ọkwa YG8 ma ọ bụ cobalt etinyere, ndụmọdụ ndị a na-edobe ịdị nkọ 8-10x ogologo karịa agụba HSS, ọbụlagodi mgbe ị na-egbutu osisi siri ike (oak, teak) ma ọ bụ igwe anaghị agba nchara.

- Mkpuchi Mgbochi Mgbochi: PVD (Vapor Deposition Anụ ahụ) mkpuchi na agụba dị ka usoro NYX SS na-ebelata okpomọkụ site na 40%, gbochie nrapanye ihe, na ịgbatị ndụ agụba 3x na nchara igwe anaghị agba nchara.

- Ihe mkpuchi na-awụ akpata oyi n'ahụ: ahụ igwe na-agbaji agbaji dị elu (HRC 65) na-egbochi ọgụ n'oge arụ ọrụ dị elu, dị oke mkpa maka igwe ịwa oyi ebe okpomọkụ gafere 600°F.

2. Geometric Innovations

- Profaịlụ eze:

- Ezé na-akara akara conical: Maka akụkụ laminate/veneer, ezé conical na-emepụta mbelata na-enweghị ihe ọ bụla site na-ebu ụzọ tụọ akara.

- Mgbochi ịma jijiji: Ọjà na-agba agba (15-25 ° helix angle) n'ime oghere osisi na-eme ka mgbapụ mgbawa dị nro, na-ebelata mkpọtụ site na 15 dB na iwepu mkpọtụ workpiece.

- Mkpọchi oblique: Patented 45–90º mkpọsa akụkụ n'ime agụba chịkọtara na-eme ka nkwụsi ike, na-ebelata nchụpụ nha nha n'oge ịkpụ nchara dị arọ.

3. Nhazi nkenke

- Nkwụsi ike nke Laser-calibrated na-eme ka mgbakasị ahụ ≤0.1mm, ọbụlagodi na dayameta 660mm. Nke a na-egbochi mgbagha mgbe ị na-egbutu tubes igwe anaghị agba nchara, na-ejigide ikike ịkpụ n'ime ± 0.2mm.

Arụmọrụ Uru: Gafere Ọsọ na Ogologo Ndụ

- Ngwakọta ihe dị iche iche

Otu usoro NYX agụba na-agbanwe n'enweghị nsogbu n'etiti:- Ọla: ígwè arụrụ arụ, aluminom (Bosun MAG350120L agụba bechapụ aluminom na 3,000 RPM), na igwe anaghị agba nchara.

- Ngwakọta osisi: Osisi siri ike, MDF, na laminates phenolic na-enweghị ndọkasị.

- Ịrụ ọrụ akụ na ụba

- Ogologo ndụ agbatịkwuru: 2–3x ogologo oge ọsọ karịa ọkọlọtọ ọkọlọtọ—awa 20–24 na red sandalwood vs. 8 awa maka carbon ígwè.

- Nchekwa ike: geometry eze kachasị mma na-ebelata ike ike site na 18% na ngwa ịkpụ oyi.

- Ogo elu & Nchekwa

- Akụkụ Burr-Free: Teknụzụ ịkpụ oyi na-eme ka akụkụ ọrụ dị jụụ, na-egbochi mgbagha ọkụ na iwepu mmecha nke abụọ.

- Njikwa uzuzu: Atụmatụ ọjà na-ejide 95% nke ibe osisi, na-ebelata irighiri ikuku.

Ngwa-kpọmkwem Ngwọta: agụba dakọtara na ọrụ

Nrụ ọrụ igwe nrụpụta

- Ngwongwo-nri dị arọ: NYX DS PVD blades (660mm) nwere ezé 180 na-egbutu akwụkwọ ntanye siri ike na 60-380 m/min. Amanyere iwu ka mmiri jụrụ oyi.

- Igwe anaghị agba nchara: CHAOS usoro agụba (400mm) na-eji ezé 4-flute TCT gbue tubes nwere mgbidi dị mkpa (minti 5) na-enweghị ọdịda.

Ịrụ osisi & Ngwakọta

- Bandsawing Hardwood: TCT bandsaw na-egbutu osisi oak na 25 m/s — ọsọ nke eriri carbon ugboro abụọ—na ọkụ efu.

- CNC Machining: 25° spiral-angle router bits na-eme ka ọnụego nri 2x ọsọ ọsọ na MDF ihe osise vs. ogologo ibe n'ibe.

Ọpụrụiche ịcha

- Nrụpụta Aluminom: 120-eze agụba (Bosun MAG350120L) na-egbochi ịta ahịhịa site na nha nha bevel ọzọ.

- Panel Laminated: Mpempe akara akara na-agbanwe agbanwe na-emepụta kerfs enyi na enyi dị gịrịgịrị ka 2.0mm.

Tebụl: Ntuziaka nhọrọ TCT Blade site na ihe

| Ụdị ihe | Usoro agụba | Nkọwapụta igodo | Ọnụego nri kacha mma |

|---|---|---|---|

| Igwe anaghị agba nchara | NYX SS PVD 6 | 180 ezé, Ø225-660mm | 40–80 m/min |

| Osisi siri ike | TCT Spiral 5 | 15–25° helix, 0.45x isi ruru | 8–12 m/min |

| Aluminom | Bosun MAG 8 | 120 ezé, Ø350mm | 25–40 m/min |

| Concrete/Re-ogwe | SDS Plus 2 | 4-ọjà, ndụmọdụ carbide YG8 | 10–150 m/min |

Ndụ agụba na-ebuli elu: Usoro mmezi

- Ịdọ aka ná ntị jụrụ oyi: emulsions mmiri na-agbaze bụ iwu maka ịcha ígwè; Mbelata akọrọ naanị akwadoro maka osisi n'okpuru ọkpụrụkpụ 20mm.

- Nyocha eze: Lelee maka mgbaji carbide kwa awa 50 arụ ọrụ-dochie ma ọ bụrụ na chipping karịrị 0.3mm.

- Nchekwa: Kpọgidere kwụ ọtọ na oghere ihu igwe na-achịkwa; iru mmiri> 60% na-eme ka corrosion ígwè dịkwuo elu.

Ọdịnihu Edge: Smart Blades na Industry 4.0

Akara TCT nke na-esote na-agbakwunye ibe RFID iji soro nha nha nha na igbu oge, na-emekọrịta na sistemụ CNC maka ọkwa na-amụba akpaaka. Ka ọ dị ugbu a, mkpuchi mkpuchi carbide nano-layered (n'okpuru mmepe) na-ekwe nkwa ndụ 5x na igbutu titanium.

Mmechi: Nkenkenke dị ka ọkọlọtọ

TCT hụrụ agụba gafere ọrụ ha dị ka ngwa ịkpụchasị ihe—ha bụ sistemu eji arụ ọrụ na-ejikọta ọla, geometry, na ike. Ma slicing igwe anaghị agba nchara tubing na micron-level ma ọ bụ na-akpụ osisi siri ike na nka finesse, ha na-enye arụmọrụ enweghị ntụpọ. Maka ndị na-emepụta ihe na-achọ mmepụta ihe mkpofu efu ma ọ bụ ndị na-arụ ọrụ osisi na-achọ ihe ngosi gallery-njikere, itinye ego na teknụzụ TCT kpọmkwem abụghị nhọrọ-ọ bụ ihe mgbakwasị ụkwụ nke nka nka.

Oge nzipu: Jul-20-2025